Modular Panel Data Centers

High-Performance, Rapid-Deployment Composite Envelopes for Mission-Critical Infrastructure

Modular Brands delivers next-generation data center buildings engineered with advanced LiteSIP composite structural insulated panels (C-SIPs). Our systems provide unmatched thermal performance, corrosion-proof durability, and ultra-fast construction timelines — enabling hyperscale, edge, and enterprise operators to deploy capacity faster, run more efficiently, and maintain high uptime.

Our envelopes are engineered for speed, efficiency, and environmental precision across all climates.

Why Composite Panel Data Centers?

Rapid Deployment

Buildings erected up to 4× faster than traditional steel-and-concrete construction.

Off-site fabrication and just-in-time shipping accelerate project schedules dramatically.

Perfect for multi-phase expansions and fast-response compute demands.

Superior Thermal Performance

Continuous high-R insulation (R-28 to R-56).

Zero thermal bridging due to composite skins.

Significantly lower HVAC loading and operational energy costs.

High Security & Durability

Non-organic composite materials resist corrosion, moisture, mold, and rot.

High impact resistance for perimeter structures and sensitive environments.

Optional enhanced skins for increased security applications.

Precision Environmental Control

Airtight, monolithic envelopes maintain consistent internal temperature and humidity.

Ideal for high-density compute, UPS rooms, battery halls, generator buildings, and switching rooms.

Scalable Production Capacity

Up to 600,000 sq ft of panels per month.

Domestic and international manufacturing partnerships for redundancy and scalability.

Large-campus and multi-building deployments supported.

Panel Technology: LiteSIP Composite Structural Insulated Panels (C-SIPs)

Our proprietary LiteSIP C-SIP panels provide a high-performance envelope unmatched by any traditional construction method.

Panel Specifications

Skins: Advanced fiber-reinforced composite

Core Options: High-density polyurethane or EPS

Thickness: 4”, 6”, 8”, custom

R-Values: R-28 to R-56+

Panel Sizes:

Standard: 8’×20’, 8’×32’, 8’×36’

Custom lengths up to 50’+ depending on logistics

Finishes: Smooth composite skins ready for painting/cladding; manufactured in any color, texture, or reflectivity.

These panels create a unified, airtight enclosure with exceptional thermal stability, structure, and low operational cost.

Applications & Use Cases

Our composite-panel systems are ideal for:

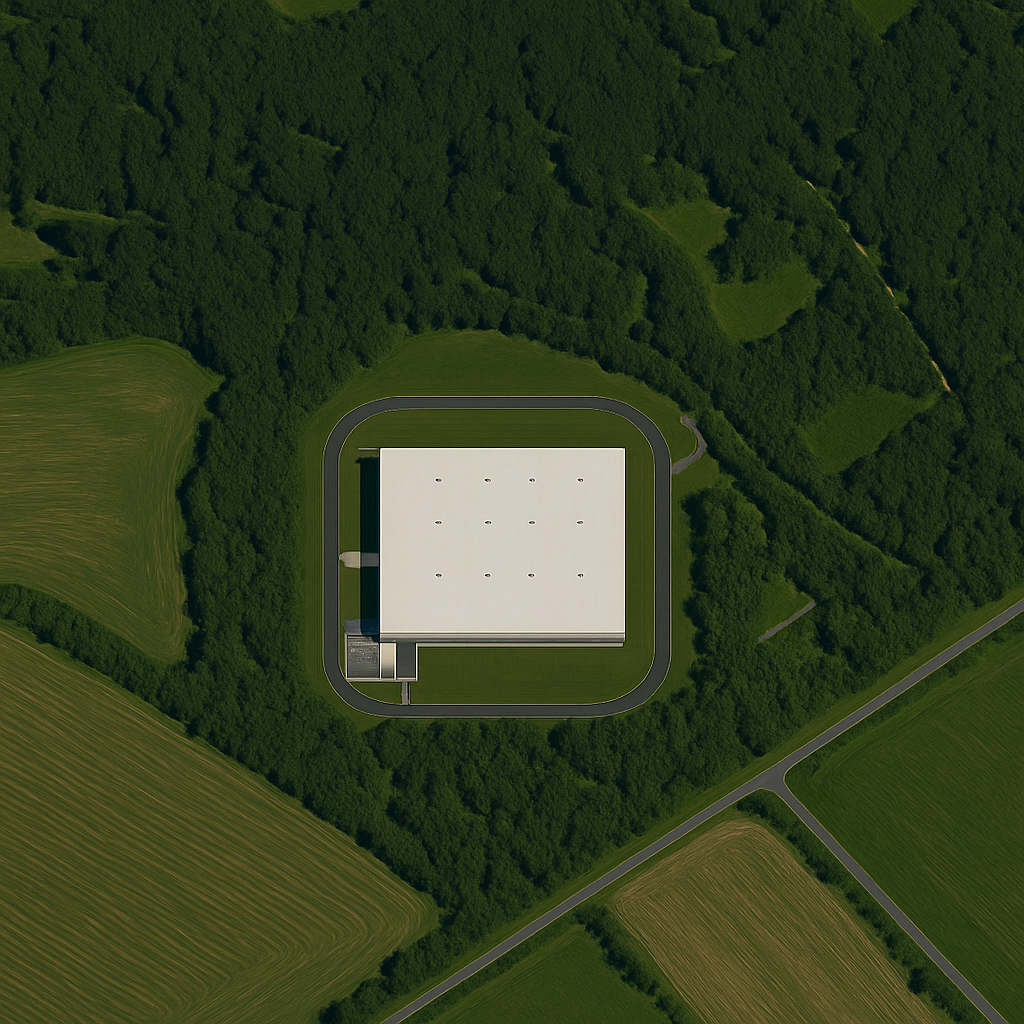

Hyperscale compute campuses

Enterprise data centers

Edge compute facilities

Battery/UPS rooms

Generator & mechanical buildings

Switching/telecom nodes

Cold aisle containment environments

AI compute clusters

High-security infrastructure enclosures

Manufacturing, Logistics & Installation

-

Manufacturing

High-volume output

Flexible configurations for custom performance requirements

Rigorous QA/QC at every stage

-

Logistics

Nationwide and international delivery

Flatbed, container, over-the-road shipping

Staged or phased delivery for large campus rollouts

-

Installation

Certified Modular Brands installation partners through KTM

On-site supervisors or full turnkey install options

Training available for regional crews

Seamless integration with GC teams, architects, and MEP engineers

Deployment Advantages for Data Centers

Reduced Foundation Load

Lightweight composite assemblies reduce foundation requirements, shipping cost, and installation labor.

Weather-Independent Construction

Panels can be installed in nearly any weather condition, minimizing delays and improving schedule reliability.

Integrated Mechanical Flexibility

Easy integration with rooftop units, cable trays, chases, fire systems, and conduit routing.

Fire & Code Compliance

Class-A options, engineering reports, load tables, and stamped documentation provided for all jurisdictions.

Engineering Documentation & Compliance

Upon request, Modular Brands provides:

Structural engineering packages

Load tables, seismic, dead/live load data

Fire ratings and MSDS documentation

Materials certifications

Shop drawings & assembly diagrams

Code compliance & AHJ documentation (IBC, NFPA, ASHRAE, Uptime Institute envelope guidelines)

Partner With Modular Brands

Modular Brands is ready to support fast-moving, high-demand data center programs requiring speed, precision, and scalable manufacturing capacity.

We assign a dedicated project manager and collaborate closely with your architectural, engineering, and construction teams from early concept through final commissioning.

Contact Our Data Center Division

Derek Kern, Executive Administrator

Derek@mdlrbrands.com